HISTORY

Year 1964

Koken-sha Ltd. was founded in Fukuoka-city

Year 1947

Reorganized and renamed as Koken Shisui Co., Ltd.

Year 1948

- Headquarters moved to Meguro-Ku in Tokyo

- A large boring machine was developed to research coal resources and supplied to coal mines like the Mitsui Miike coal mine.

Year 1949

Japan’s first high-speed rotation machine, “KB drill,” was developed.

Year 1952

- The hydraulic boring machine was supplied to the Tokyo Metropolitan

Government Bureau of Waterworks for Ogauchi dam construction. - A high-speed boring machine was supplied for Sakuma Dam. We further expanded the business into the civil engineering and construction industry.

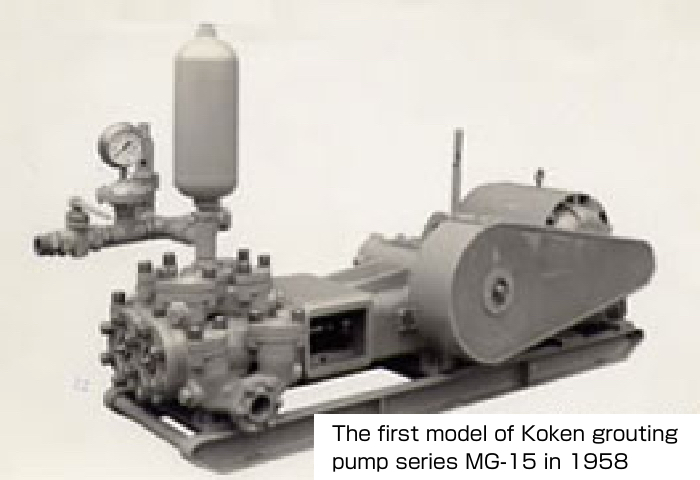

Year 1957

The world’s first submarine boring machine was developed and

supplied for research of undersea coal mines.

supplied for research of undersea coal mines.

Year 1959

The first mixing plant in Japan was supplied for the Kurobe Dam construction.

Year 1964

Japan’s first all-hydraulic boring machine was developed and supplied for subway construction in Tokyo.

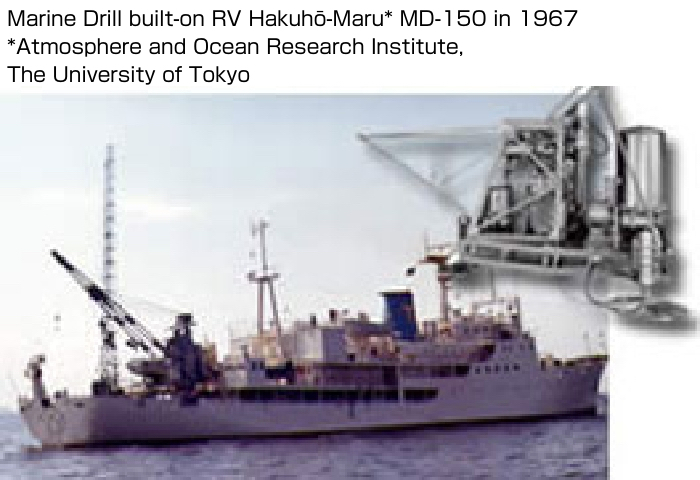

Year 1967

- A remote-controlled submarine boring machine, “Marine Drill,” was developed and supplied that was built on the research vessel “Hakuhō-Maru”.

- The first large borehole drilling machine, “BIGMAN BM-1,” was developed.

Year 1968

The Atugi factory was built at the industrial park in Atugi city, Kanagawa pref.

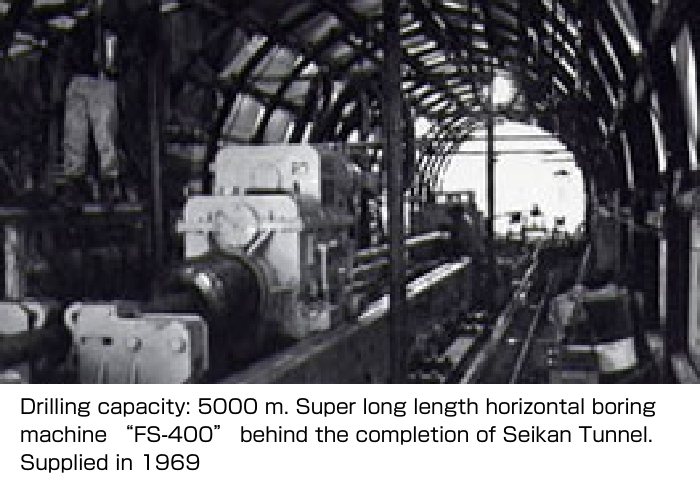

Year 1969

One of the world’s largest horizontal boring machines, “FS-400,” which had been supposed to drill 5,000 m in the Seikan Tunnel, was developed and supplied for Japan Railway Construction Public Corporation.

Year 1971

The large borehole drilling machine “BIGMAN N” series was developed.

Year 1972

One of the world’s largest mixing machines for prepacked concrete was developed with the Honshu-Shikoku Bridge Authority and supplied.

Year 1973

- A super-high pressure grouting pump, “PG pump,” was developed.

- The first overseas office at that time was established in Singapore.

Year 1975

- The first all-hydraulic rotary and percussion machine, “Arrow drill RPD-1” in Japan was developed.

- The long-length horizontal boring machine “BED-100” was developed for advanced drilling in the Seikan Tunnel by a new drilling method that pressurizes circulating water and is supplied for Japan Railway Construction Public Corporation.

Year 1977

- Shield raise boring machine “UPB-75” was developed for a boring vertical shaft.

- “Arrow drill RPD-65” was developed. That spread the opportunity to adopt an anchor drilling method in Japan.

- The large borehole drilling machine “BIGMAN CIVIL RBB-100” was developed.

Year 1978

- A remote-controlled submarine boring machine, “Marine Drill,” was developed and supplied that was built on the research vessel “Hakuhō-Maru”.

- “ICE DRILL MID-140” was developed and supplied to the National Institute of Polar Research for Antarctic research.

- Koken Atsugi factory was completed in 1968, and the surrounding area

- Drilling capacity: 5000 m. Super long-length horizontal boring machine “FS-400” behind the completion of Seikan Tunnel. Supplied in 1969

- Honshu-Shikoku bridge. Underwater prepacked concrete work.

Year 1981

Koken Technical Training Center was established in Shnsyu Enrei Plateau Park.

Year 1982

- Headquarters moved Meguro-ku to Nakano-ku in Tokyo

- Koken’s maintenance department was developmentally established as a spin-off and started 100 %-owned by Koken Machine Service Co., Ltd.

- Full automatic concrete batching plant “Captain” was developed and contributed to work saving and cleanup in civil engineering and construction work.

- “Down The Hole, Drill DD-10” was developed.

Year 1984

- A rotary percussion drill and rail-mounted grouting plant were supplied for tunnel construction of Baikal–Amur Mainline in post-Soviet states.

- Computer-controlled submarine boring machines “Marine Drill MDC-200/10” “MDC-100/100AH” and its marine geological survey tools were developed and supplied for offshore oilfields in Sakhalin, post-Soviet states.

Year 1985

TG-NKK long-distance propulsion tunneling method and dedicated model “FS-120” was co-developed by Tokyo Gas (TG) and Nippon Steel Pipe (NKK) and us.

Year 1986

- The computer-controlled boring robot “ADS-15” was co-developed by Tokyo Electric Power Company (TEPCO) and us.

- Renamed Koken Boring Machine Co., Ltd. at the 40th anniversary of the foundation.

Year 1988

Koken Technical Training Center and a small earth science museum were built in Shnsyu Enrei Plateau Park.

Year 1991

The first prototype machine aimed at Mars exploration was developed by the Institute of Space and Astronautical Science (ISAS), volunteers of Nagoya University, Nishimatsu Construction, Nippon Denso, and us.

Year 1992

- Koken Suwa factory was built in Nagano pref. In the same period, another technical center was also built.

- One of the world’s largest rotary percussion drills, “Arrow drill RPD-200,” was developed.

Year 1993

- The raised boring machine “BM-150” was developed. It was used for Oku-kiyotsu power plant construction in Niigata pref, on the targets: drilling diameter (1.5m), drilling length (250m), and tilt angle (51 degrees).

- A Percussion Wireline Sampler was developed.

Year 1994<

Registered for Japan Securities Dealers Association (JSDA) and over-the-counter trading started.

Year 1995

- Restoration work for The Great Hanshin-Awaji Earthquake Disaster in Japan.

- We held a 100% stake in Kozo Kouji Co., which became a subsidiary,

- Japan Home Water System Co. was established for the purpose of developing household water wells.

Year 1997

Koken Earth Museum “地球の宝石箱” was built as a commemorative project for the 50th anniversary of its founding in Shiojiri-city, Nagano pref.

Year 1998

- Koken Machine Service Co., Ltd (subsidiary) was renamed as Boring Techno Service Co., Ltd.

- Meisho Co., Ltd, which manufactured grout flow meters, was established.

Renamed in 1987.

Koken earth museum “地球の宝石箱” opened in 1997.

Year 2000

The first overseas production bases were established.

Year 2002

One of the largest raise boring works succeeded on the targets: drilling dia (1.5m), drilling length (250m), and tilt angle (51 degrees) at the site of Tsukumi mine (Oita pref) by Todaka Mining Co., Ltd.

Year 2003

- The soil sampling machine, “Sonic Drill ED-15”, was developed. It had the capacity to drill up to 10 m in depth, even on hard formations.

- A sound-proof and super pulse vibration drilling machine, “K-50”, realized by a unique drill-head (patented), was developed. It had been in compliance with noise regulations in urban civil engineering sites in Japan.

- A multi-purpose crawler drilling machine, “S-150,” was developed that targeted China, Southeast Asia, and EU markets as well as domestic markets.

Year 2004

- House foundation drilling machine “FSP-50AC” was developed. It had a multi-feeding system and realized 8m long-stroke work while it was a small machine.

- A sound-proof and super pulse vibration drilling machine, “K-150,” was developed.

- Over-the-counter trading ended and got listed on JASDAQ.

Year 2006

Headquarters moved Nakano-Ku to Toshima-Ku in Tokyo

Year 2008

The large borehole boring machine (outer diameter 6m) “BM-600” was developed.

Year 2010

- The horizontal directional boring machine “FSC-100” was developed for investigation.

- Became listed on the new JASDAQ market as the result of the Osaka Securities Exchange (OSE) merging the JASDAQ Securities Exchange with OSE’s NEO and Nippon New Market-Hercules (HC) markets.

Year 2012

All hydraulic rotary percussion drill “RPD-160C” was developed with a new drill head “KD-1200” equipped.

Year 2013

- The takeover of a consolidated subsidiary, Meisho Co., Ltd.

- Became listed on the Tokyo Stock Exchange (TSE) JASDAQ “STANDARD” market as the result of the integration of the Osaka Securities Exchange (OSE) and the Tokyo Stock Exchange (TSE).

- The horizontal drilling machine “FS-120CZ” was developed for emergency rescue work.

Year 2015

Transition to a company with an audit and supervisory committee.

Year 2016

- Yangon branch was established as an overseas base in Myanmar.

- The spindle-type boring machine “KT-100” was manufactured overseas.

Year 2018

All hydraulic rotary percussion drill “RPD-180C” was developed with an engine in compliance with the 4th gas regulations in Japan.

Year 2019

Capital and business alliance with Enbio Holdings, Inc.

Year 2020

- Entered into a contract for acquiring land and buildings in the Isehara Industrial Park and transferring land and buildings for the Atsugi factory.

- Initiated development of next-generation products focusing on safety, labor-saving, and productivity improvement. Started the design and fabrication of two models of medium-sized RPD machines: RPD-75SHF and RPD-70-DFC, three models of rod handling devices, medium-capacity piston pump MG-60V, ultra-high pressure pump PG-150V, and medium-sized automated plant KMPA-VM1000.

Year 2022

Transitioned to the Standard Market due to the market reorganization of the Tokyo Stock Exchange.